In the competitive world of personal care and cosmetics, the quality of a product is judged not only by its formula but also by its delivery. For luxury perfumes, moisturizing mists, and sensitive skin sprays, packaging integrity is paramount. This is where advanced technology takes center stage. Modern aerosol filling machines play a critical role in ensuring that these high-value products are packaged with uncompromising safety, precision, and elegance. Specifically, using a dedicated aerosol filling machine for perfume and skin spray is no longer a luxury but a necessity for brands that prioritize quality and consumer trust. This article explores how this technology safeguards your product and your brand reputation.

Why Precision is Non-Negotiable in Cosmetic Aerosols

The margin for error in cosmetics and perfumery is virtually zero. Inaccurate fills have immediate consequences:

-

Brand Image Damage: An under-filled can of luxury perfume suggests poor quality and cheats the customer, damaging a premium brand's image.

-

Inconsistent User Experience: Over-filling or inconsistent dosing in a moisturizing spray can alter the fine mist pattern, affecting application and satisfaction.

-

Profit Erosion: "Product giveaway" through over-filling, especially with expensive fragrances and active ingredients, directly cuts into profitability.

A specialized aerosol filling machine eliminates these risks through servo-driven precision, ensuring every unit is perfect.

Key Features of a Machine Built for Personal Care Products

Not all filling lines are created equal. Packaging delicate skin sprays and perfumes requires specific engineering.

1. Gentle Handling for Delicate Containers and Formulas

-

How it Works: Machines designed for the personal care sector, like the 25.4mm Valve Automatic BOV Line, often feature aluminum-specific handling to prevent scuffing or denting elegant cans. Furthermore, they use piston filler technology that gently meters product without shearing or degrading delicate emulsions and fragrance blends.

-

Impact on Safety & Quality: This ensures the final product is visually flawless and that the formula's integrity is maintained from the tank to the can.

2. Unmatched Dosing Accuracy for High-Value Liquids

-

How it Works: Programmable Logic Controllers (PLCs) and high-accuracy piston fillers work in tandem to dispense an exact, pre-programmed amount of product and propellant every time. This is the core function of a precision aerosol filling machine for perfume.

-

Impact on Safety & Quality: This guarantees that every single canister has the perfect propellant-to-concentrate ratio, ensuring a consistent spray pattern, droplet size, and dosage with each use. Customers get the identical experience from the first spray to the last.

3. Closed-System Filling to Ensure Purity and Safety

-

How it Works: The entire filling and gassing process occurs within a sealed, closed-loop system. This is critical when filling products for skin application.

-

Impact on Safety & Quality: This hermetic barrier prevents external airborne contaminants from entering the product and stops volatile organic compounds (VOCs) from escaping into the factory environment. It ensures product purity and creates a safer workplace for operators.

4. Secure Crimping and Leak Testing for Product Integrity

-

How it Works: The machine automatically places the valve onto the can and crimps it with consistent, precise pressure. The line then includes a water bath test, where every can is immersed in heated water to visually identify any micro-leaks.

-

Impact on Safety & Quality: A perfect crimp and seal prevent leaks during storage and transport, preserving the product's volume and potency. This step is critical for maintaining shelf life and preventing customer complaints about faulty cans.

Case in Point: The 25.4mm BOV Aerosol Filling Line for Perfume

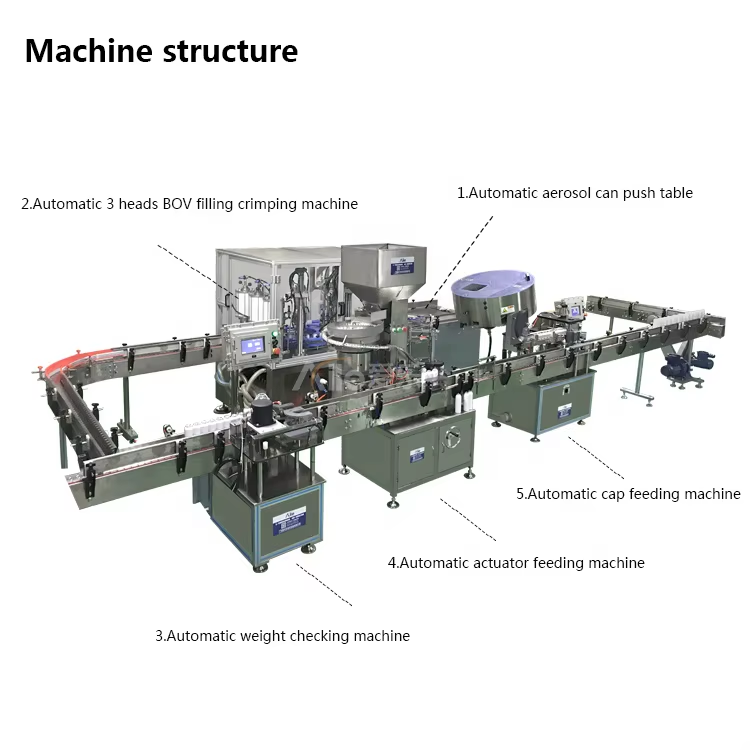

The 25.4mm Valve Aluminum Multifunction Full Automatic BOV Aerosol Filling Production Line from Aile Aerosol is a prime example of a machine engineered for this elite role. Its design embodies all the principles of safe and precise packaging:

-

Specialized for Aluminum Cans: Gently handles the containers typical of high-end cosmetic and perfume products.

-

BOV (Bag-On-Valve) Compatibility: BOV technology is ideal for skin sprays and perfumes as it separates the product from the propellant with a membrane, ensuring the formula remains pure and uncontaminated and allows for 360-degree spraying.

-

Full Automation: The integrated line handles filling, gassing, crimping, and testing without manual intervention, minimizing human error and contamination risk.

-

GMP Compliance: Built with materials and design principles that support compliance with Good Manufacturing Practices, essential for cosmetic manufacturing.

Conclusion

The role of an aerosol filling machine in packaging extends far beyond simply putting a liquid into a can. It is the guardian of your product's quality, your brand's reputation, and your consumers' safety. For manufacturers of perfumes, moisturizing sprays, and other personal care aerosols, investing in a specialized aerosol filling machine for perfume and skin spray is a strategic decision to achieve unparalleled precision, ensure utmost safety, and deliver the flawless user experience that the modern market demands. In an industry where details matter, the right packaging technology makes all the difference.

FQA (Frequently Asked Questions)

1. Q: What is BOV technology, and why is it better for skin sprays and perfumes?

A: BOV (Bag-On-Valve) uses a small pouch inside the canister to hold the product, separate from the propellant. This prevents the product from contacting the propellant, preserving its integrity, fragrance, and viscosity. It also allows for dispensing non-aerosol products like creams and allows the can to be sprayed at any angle.

2. Q: How does an automatic filling line improve safety for cosmetic products?

A: It improves safety through a closed-loop system that prevents contamination, precision dosing that ensures formula consistency, and automated crimping/leak testing that guarantees package integrity and prevents spoilage.

3. Q: Can one machine handle both perfume and moisturizing spray production?

A: Yes, a versatile and well-configured automatic line like the one discussed can be used for various products within the personal care sector, often with quick changeovers between similar formulas and can sizes.

4. Q: What kind of accuracy can I expect from a precision aerosol filler for cosmetics?

A: High-end machines offer fill weight accuracy within ±1%, ensuring no product giveaway and consistent customer experience.

5. Q: Is the water bath test necessary if the crimping is automatic?

A: Yes. The water bath test is a critical quality control check. Even with precise crimping, it serves as a final verification step to identify any micro-leaks in the valve seal that would be invisible to the naked eye, ensuring a 100% leak-free batch.