The packaging industry is rapidly evolving, with automation leading the charge towards greater efficiency, accuracy, and scalability. For many businesses, particularly growing food and specialty brands, the future of packaging isn't about choosing between fully manual or fully automatic systems—it's about finding the smart, scalable technology that fits their current needs and budget. This is where advanced semi-automatic aerosol filling machines shine, offering a powerful blend of human oversight and mechanical precision. This article explores how this technology, exemplified by dual-head systems, serves as the cornerstone of efficient, modern packaging and a strategic stepping stone to full automation.

The Efficiency Gap: Beyond Manual Labor

Many small to medium-sized producers start with manual filling, but they quickly encounter bottlenecks that hinder growth:

-

Inconsistent Fills: Hand-operated pumps lead to product giveaway or under-filling, eroding profits and brand trust.

-

Slow Production Speeds: Manual processes are inherently slow, creating inability to meet larger orders.

-

High Labor Dependency: The process is labor-intensive, tying up skilled workers on repetitive tasks.

A semi-automatic aerosol filling machine directly addresses these inefficiencies, serving as a critical upgrade that future-proofs operations.

Why a Semi-Automatic Dual Aerosol Filling Machine is a Strategic Choice

For businesses not yet ready for a full turnkey line, a semi-automatic dual-head machine represents the perfect balance of performance, cost, and flexibility.

1. Dual-Head Operation for Doubled Output

-

How it Works: Unlike single-head machines, a semi-automatic dual aerosol filling machine features two independent filling heads that operate simultaneously. An operator places two cans, initiates the cycle, and both are filled and gassed in the same time it would take to process one.

-

Impact on Efficiency: This simple feature effectively doubles your production output compared to a standard semi-automatic machine, drastically reducing bottling time and labor costs per unit without a massive capital investment.

2. Uncompromising Precision for Product Consistency

-

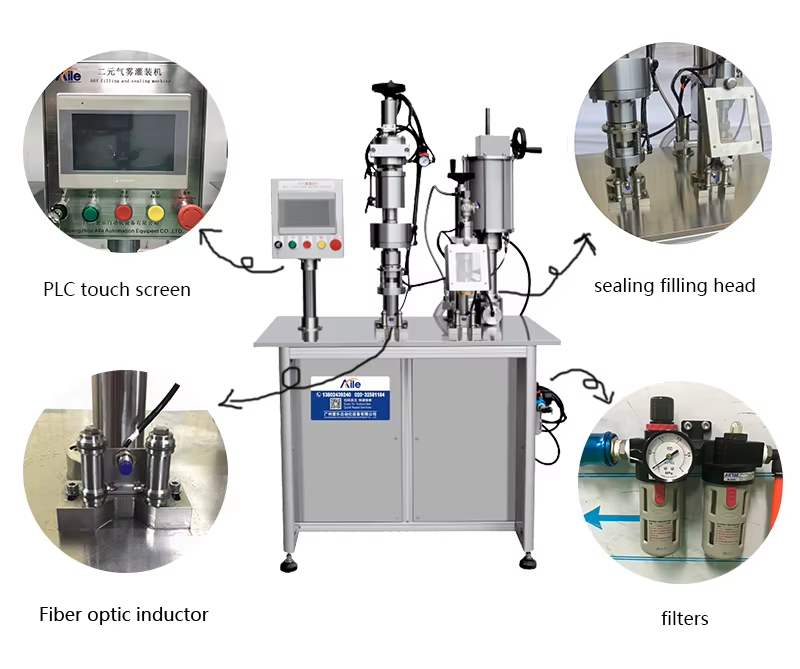

How it Works: These machines replace guesswork with engineering. They utilize precision piston fillers and adjustable timers or PLCs to ensure each can receives an exact, pre-set amount of product and propellant.

-

Impact on Efficiency: This precision eliminates costly product giveaway and guarantees that every unit, whether it's olive oil spray or a specialty chemical, meets the exact same quality standard. This reduces waste and protects your profit margins.

3. Easy Operation and Minimal Training

-

How it Works: The "easy-to-operate" design is a key feature. With intuitive controls and a simple foot pedal or button operation, the learning curve is incredibly short.

-

Impact on Efficiency: You can quickly train existing staff to operate the machine efficiently. This minimizes downtime and allows for flexible staffing, as it doesn't require a highly specialized engineer to run.

4. Flexibility for Small Batches and R&D

-

How it Works: Semi-automatic machines are ideal for small batch production, limited edition runs, and Research & Development. Changing products or can sizes is typically quick and straightforward.

-

Impact on Efficiency: This flexibility allows brands to be agile, test new markets with lower risk, and produce a wide variety of products on a single machine without the long changeover times of a large automated line.

Case in Point: The Semi-Automatic Dual Aerosol Filling Machine for Olive Oil Spray

The Easy-to-Operate High Efficiency Replenishing Olive Oil Spray Semi-Automatic Dual Aerosol Packaging and Filling Machine from Aile Aerosol is a perfect embodiment of this efficient future. It is specifically designed for applications like food-grade sprays:

-

Dual-Head Design: Maximizes output for growing food brands that need more efficiency than a manual process but don't require a massive linear line.

-

Food-Safe Considerations: Built with materials suitable for contact with food products like olive oil.

-

Precision for Value: Ensures accurate filling of high-value products, directly protecting profitability.

-

Easy Integration: Serves as a standalone workhorse that can be easily incorporated into an existing workshop without major infrastructure changes.

Conclusion

The future of efficient packaging is not a one-size-fits-all approach. For countless businesses, the most logical and profitable step forward is a semi-automatic dual aerosol filling machine. This technology provides a crucial competitive advantage by dramatically improving speed, accuracy, and consistency over manual methods, all while maintaining a manageable level of investment and operational complexity. It is the ideal solution for growing brands in the food, cosmetic, and specialty chemical industries that are ready to embrace the future of automated packaging on their own terms.

FQA (Frequently Asked Questions)

1. Q: What is the main difference between semi-automatic and fully automatic aerosol filling machines?

A: A semi-automatic machine requires an operator to manually place and remove cans for each filling cycle, while a fully automatic line uses an automated conveyor system to move cans through the entire process (unscrambling, filling, crimping, gassing) with minimal human intervention. Semi-automatic offers a balance of control and efficiency; full automatic maximizes speed and minimizes labor.

2. Q: Is a semi-automatic machine suitable for high-volume production?

A: While not as fast as a large rotary automatic line, a dual-head semi-automatic machine is significantly faster than manual filling and is perfectly suited for small to medium-volume production, batch processing, and pilot runs.

3. Q: How difficult is it to change the product or can size on this machine?

A: Changeovers are relatively simple. They typically involve adjusting the filling head height and changing the filling nozzles or sealing heads to accommodate different can diameters and product viscosities. This makes it highly flexible for producers with multiple SKUs.

4. Q: What kind of training is required to operate this machine?

A: The operation is designed to be intuitive. Basic training usually covers machine startup, filling volume adjustment, can positioning, and routine cleaning. Most operators can become proficient within a few hours.

5. Q: Can this machine handle different types of propellants?

A: Yes, provided it is equipped with the appropriate gas filling head. These machines can typically be configured to handle compressed gases (like N2 or CO2) and liquefied gases (like LPG or DME). It's important to confirm the specifications with the manufacturer for your specific application.