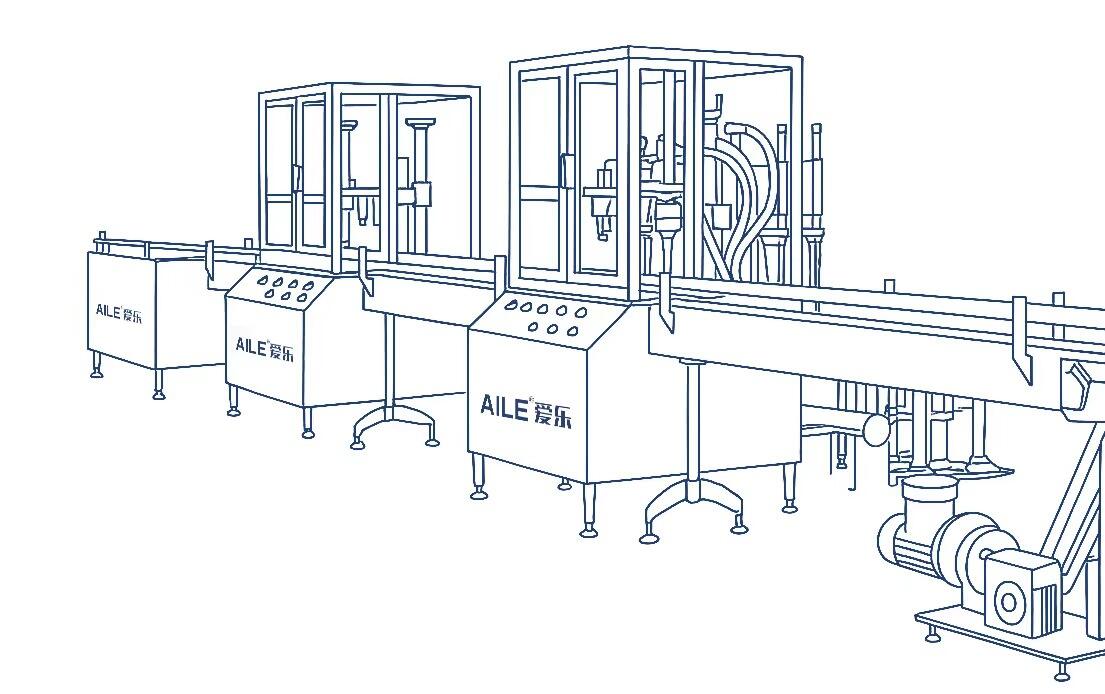

Selecting the right equipment is one of the most critical decisions for an aerosol manufacturer. A well-chosen automatic aerosol filling machine can revolutionize your production, driving efficiency, ensuring impeccable quality, and delivering a rapid return on investment. However, navigating the myriad of options can be daunting. This comprehensive guide provides a structured framework to help you choose automatic aerosol filling machine technology that is perfectly tailored to your specific products, capacity needs, and business goals. We'll use the versatile Cassette Furnace Spray Production Line from Aile Aerosol as a prime example of a well-engineered, tailored solution.

6 Key Factors to Consider When You Choose an Automatic Aerosol Filling Machine

Making an informed choice requires a thorough analysis of your own operation and the capabilities of the machinery. Here are the six essential areas to evaluate.

1. Define Your Primary Product and Formula Characteristics

The physical and chemical properties of your product are the foremost deciding factor. A machine designed for thin solvents will struggle with viscous creams.

-

Viscosity: Is your product a thin liquid, a thick gel, or a suspension with particulates (e.g., snow spray or hair color)?

-

Product Type: Are you producing industrial cleaners (e.g., cassette furnace spray), cosmetics (e.g., disposable hair color spray), or novelty items (e.g., snow spray)? Each has different purity and accuracy requirements.

-

Propellant Type: Does your formula use LPG, DME, or compressed gas? The gassing system must be compatible.

Why it matters: The Aile Aerosol Cassette Furnace Spray Line is engineered to handle a diverse range of viscosities and formulas, from aggressive chemical cleaners to pigmented cosmetic sprays. Matching the machine to your product prevents clogging, ensures accurate dosing, and maintains product integrity.

2. Determine Your Required Production Capacity

Your target output dictates the size and automation level of the machine you need. Understanding your capacity needs is crucial to choose automatic aerosol filling machine models that won't bottleneck your growth.

-

Low Volume: Semi-automatic machines may suffice.

-

Medium to High Volume: A fully automatic linear or rotary filling line is essential for maximizing efficiency.

-

Future Growth: Select a system with scalable capacity or a higher output than your current needs to accommodate business expansion.

Why it matters: An automatic line like the one from Aile Aerosol is designed for continuous, high-speed production, transforming a manual bottleneck into your most efficient asset.

3. Prioritize Precision and Accuracy Needs

For high-value products or those with expensive ingredients, precision is non-negotiable and directly impacts profitability.

-

Look For: Machines equipped with servo-driven piston fillers and PLC controls that guarantee fill weight accuracy within ±1%. This eliminates product giveaway from over-filling and customer complaints from under-filling.

Why it matters: Inconsistent dosage in a product like hair color spray leads to rejected batches and brand damage. The precision of an automatic aerosol filling machine is a direct driver of quality and profit.

4. Evaluate the Level of Automation and Integration

Consider how seamless you need the entire process to be. A full turnkey line integrates several steps:

-

Empty Can Handling (Unscramblers)

-

Precision Filling & Gassing

-

Automatic Valve Placing and Crimping

-

Post-Crimping Leak Testing (Water Bath) and Coding

Why it matters: A fully automated line minimizes manual handling, which reduces labor costs, improves safety, and drastically lowers the risk of contamination or human error from start to finish.

5. Scrutinize Safety and Compliance Features

The handling of volatile propellants and solvents mandates robust built-in safety mechanisms.

-

Essential Features: Explosion-proof electrical components, leak detection systems, emergency stops, and a fully enclosed gassing station are mandatory for operator safety and regulatory compliance (OSHA, ATEX, etc.).

Why it matters: A comprehensive safety system protects your workforce and facility, ensures compliance with industry regulations, and prevents costly fines and operational shutdowns.

6. Analyze Total Operational Costs and ROI

The purchase price is only one part of the financial picture. To truly understand value, you must calculate the total cost of ownership.

-

Material Savings: Reduced product waste and propellant loss from precision filling.

-

Labor Savings: Reduced number of operators required on the line.

-

Maintenance & Downtime: Ease of servicing, availability of parts, and expected upkeep costs.

Why it matters: A higher initial investment in an efficient, precision machine often leads to a faster ROI through substantial savings on materials and labor, paying for itself over time.

Case Study: The Aile Aerosol Cassette Furnace Spray Line

This specific production line exemplifies how to choose automatic aerosol filling machine technology that is a perfect match. It’s not a generic solution; it’s built for specific challenges:

-

Product Versatility: Expertly handles diverse products like sticky cleaners, festive snow sprays, and pigmented hair colorants.

-

Precision Engineering: Guarantees consistent spray performance and customer satisfaction through exact dosing.

-

Complete Automation: Offers an integrated process from empty can to finished, tested product.

-

Safety First: Designed with necessary precautions for safe handling of industrial materials.

Conclusion

Knowing how to choose automatic aerosol filling machine equipment is a strategic skill. By meticulously analyzing your product, capacity, precision requirements, and safety needs, you can select a system that acts as a powerhouse for your business growth. The goal is to find a provider that offers not just a machine, but a tailored partnership and a long-term solution for your production challenges.

FQA (Frequently Asked Questions)

1. Q: What is the average lead time for installing a new automatic filling line?

A: Lead times can vary significantly based on the machine's complexity and customization, but typically range from 3 to 6 months from order to delivery, installation, and commissioning.

2. Q: Can one machine handle different canister sizes?

A: Yes, many automatic machines are designed to be adjustable. With change parts (like filling heads, star wheels, and height adjustments), a single line can often accommodate a range of canister diameters and heights.

3. Q: How do I know if I need a linear machine vs. a rotary machine?

A: Linear machines are often ideal for lower to medium speeds and are easier to adjust for different can sizes. Rotary machines are designed for very high-speed, high-volume production of the same can size. Your supplier can best advise based on your output goals.

4. Q: What kind of training is provided for our operators?

A: Reputable manufacturers like Aile Aerosol provide comprehensive training on operation, routine maintenance, and troubleshooting during the installation and commissioning phase. This is typically included with the purchase.

5. Q: What is the typical warranty on an automatic aerosol filling machine?

A: Standard warranties often cover parts for 12 months from commissioning against manufacturing defects. Service agreements for ongoing support are usually available.