Main Components of Aerosol Insecticides

Each aerosol insecticide contains three core components:

-

Active Ingredients: Commonly low-toxicity pyrethroid compounds such as permethrin, prallethrin, cypermethrin, allethrin, and d-phenothrin. These ingredients act quickly while maintaining high safety standards.

-

Solvents: Help dissolve and stabilize the active ingredients. Typical solvents include pharmaceutical-grade oils or alcohols.

-

Propellants: Provide internal pressure to expel the liquid as a fine mist. Modern formulations often use liquefied petroleum gases such as propane, butane, or isobutane, or environmentally friendly mixed gases.

The precise proportion, mixing uniformity, and liquid purity are critical for spray performance and product stability, making high-quality insecticide aerosol filling equipment indispensable.

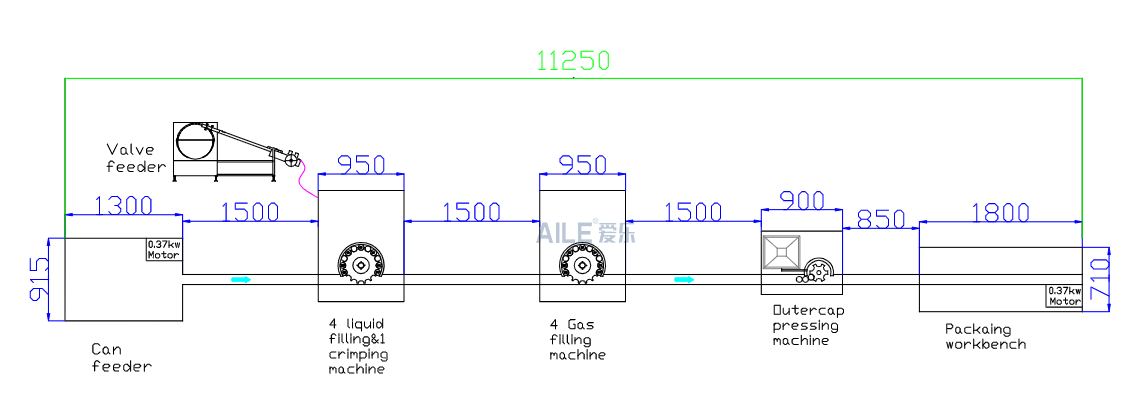

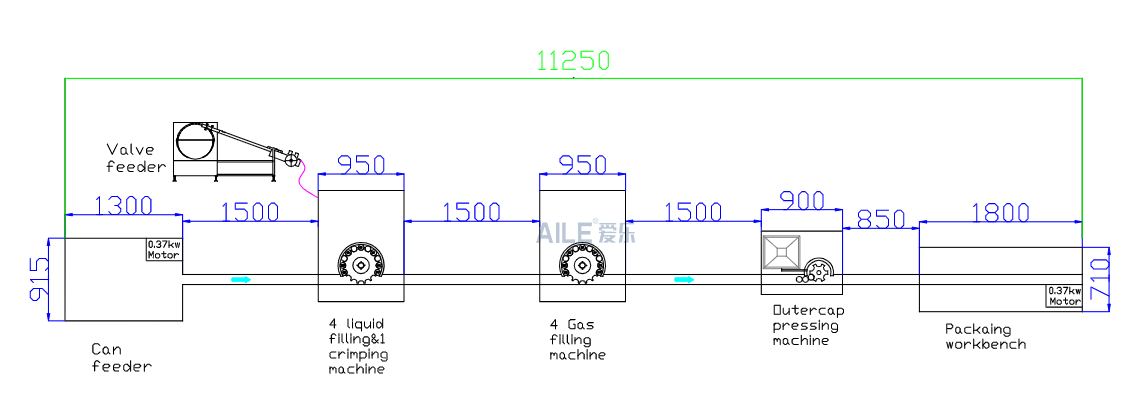

Production Process Overview

A standard aerosol insecticide production process includes:

Raw Material Preparation → Liquid Formulation → Filling & Crimping → Gas Charging → Leak & Weight Inspection → Nozzle Assembly → Packaging & Outbound

Automation level directly affects production efficiency and product quality. Modern factories often use a fully automatic aerosol filling line, capable of automatic bottle feeding, liquid filling, valve placement, crimping, gas charging, weighing, leak detection, nozzle installation, coding, and packaging. This significantly reduces human error and ensures consistency across batches.

Aerosol Filling and Crimping Section

The filling and sealing process is critical to ensure canister integrity and user safety. Typical equipment includes:

-

Liquid Filling Machine: Accurately dispenses the insecticide solution with minimal deviation.

-

Valve Placement & Crimping Machine: Automatically installs valves and crimps the cans to prevent leakage.

-

Gas Charging Machine: Fills the propellant into the canister under precise pressure control via PLC systems.

For different production scales, manufacturers can choose:

- Semi-automatic insecticide aerosol filling machines for medium or flexible production.

- Fully automatic aerosol filling lines for large-scale, high-efficiency, and continuous operations.

Some integrated three-in-one machines can perform filling, crimping, and gas charging simultaneously, reducing labor requirements and improving safety.

Quality Control and Packaging

-

Weight Check: Confirms accurate liquid and propellant ratios.

-

Water Bath Leak Test: Ensures canisters are sealed properly with no leakage.

-

Spray Test: Verifies uniform spray patterns and nozzle functionality.

-

Assembly & Packaging: Includes nozzle installation, cap attachment, coding, and final boxing.

These steps ensure that every canister meets safety and performance standards, ready for consumer use.

Recommended Production Line Configurations

| Factory Scale |

Recommended Equipment |

Features |

| Small |

Semi-automatic three-in-one machine |

Low investment, flexible production |

| Medium |

Fully automatic filling line + automatic valve placement + weighing system |

Moderate capacity, high efficiency |

| Large |

Multi-station automatic production line + automatic nozzle assembly + integrated packaging |

High automation, ideal for mass production |

All equipment can be customized to accommodate different can sizes, valve types, or environmentally friendly propellants.

Conclusion

Producing aerosol insecticides is a complex process combining chemical formulation and automated manufacturing.

From liquid preparation to filling, sealing, inspection, and packaging, high-precision aerosol filling equipment is essential for product consistency, safety, and market competitiveness.

By adopting advanced automatic aerosol filling machines and complete aerosol production lines, manufacturers can increase efficiency, reduce labor costs, and produce high-quality aerosol insecticides that meet international standards.