大気汚染や呼吸器疾患が増加する中、サルブタモールやテルブタリンなどの計量式吸入器への需要は急速に高まっています。これらのエアゾールは薬剤を肺に直接届けるため、発効が早く、投与量が少なく、的確な症状緩和が可能です。

この成長する市場ニーズに対応するため、製造業者は、各吸入剤が厳格なGMP条件下で製造され、正確なマイクロ投与および無菌充填が行われることを保証しなければなりません。

Aile Aerosolでは、医薬品用エアゾル生産に特化したカスタムエンジニアリングによる充填ソリューションを提供しており、信頼性、精度、コンプライアンスを細部まで兼ね備えています。

喘息エアゾル製造プロセスの理解:

喘息吸入器は以下の構成要素からなる複雑なシステムです:

活性成分 例えば 硫酸サルブタモール または 硫酸テルブタリン

プロペラント (例:HFA-134aまたはHFA-227ea)

添加物 共溶媒、界面活性剤、安定剤を含む

製品の安定性と一貫した投与量を確保するため、生産の各段階で厳格な管理が必要です。

吸入器(MDI)製造の主な工程:

容器およびバルブの準備

充填前の汚染リスクを排除するため、すべてのアルミ缶および計量式バルブは滅菌および乾燥されます。

処方および液体の充填

処方の種類(溶液、懸濁液、または乳剤)に応じて、薬物が正確に混合され、均一性と透明性を確保するために制御された条件下で充填されます。

プロパントの充填 – 加圧法または冷凍法

加圧充填法: 常温で制御された圧力を用いて、密閉された缶にプロパントを注入します。大規模かつ効率的な生産に最適です。

冷凍充填法: 充填前にプロペラントを零下温度まで冷却します。特定の処方には適していますが、低温システムが必要です。

漏れ検査および最終包装

充填された各缶は、ラベル貼付および梱包の前に、一貫性、正確性、安全性を確保するため、100%漏れ検査および重量検査を実施します。

医薬用エアゾールのためのAileエアゾールソリューション:

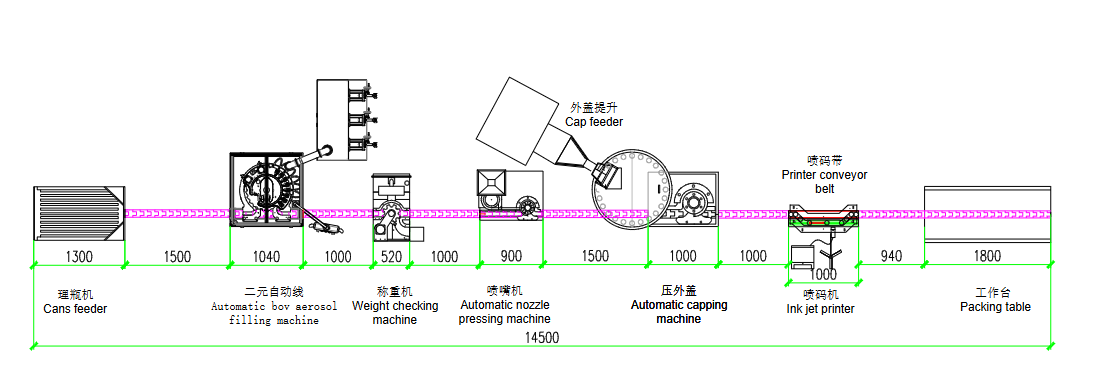

設計された 高精度医薬用エアゾール充填 、 AILE-EYQWX 液体計量、バルブ装着から圧着、プロペラント充填まで、すべての重要な工程を単一の自動化プラットフォームに統合しています。

連続的かつ高生産性が求められるMDI製造環境に最適なソリューションです。

| パラメータ | 仕様 |

|---|---|

| シール直径(mm) | 26.5-27.5 |

| シーリング深さ(mm) | 5.0-6.0 |

| 充填速度 | 1200-1800缶/h |

| 最大液体充填能力 | 300ml |

| 作業圧力 (Mpa) | 0.5-0.7Mpa |

| 液体再充填精度 | ≤±1.0% |

The AILE-EYQWJ は専用に設計されており 新薬開発 , 治験用製品の生産 および 小ロット生産 .

液体の充填、密封、ガス注入をコンパクトな一工程で統合しており、手作業の介在を減らしつつ高い精度を維持します。

| パラメータ | 仕様 |

|---|---|

| 材質 | ストック316 |

| ボトルサイズ | 直径35〜70mm、高さ80〜330mm |

| 充填速度 | 700-900 キャン/h |

| 充填範囲 | 30-500ml |

| 空気圧 | 圧縮装置 |

| 填充精度 | 1%以内 |

なぜAileのエアロゾル充填機を選ぶのか:

20年以上の実績 エアロゾル充填ラインの統合

実証済みの専門技術 医薬品グレードの少量投与アプリケーション

GMPおよびISO 認定設計および製造

カスタムエンジニアリングサポート サルブタモール、テルブタリン および類似のMDI製品向け

機械のセットアップからプロセスバリデーションまで、一貫した技術サービス

生産能力の拡張でも、新しい吸入製品の立ち上げでも、 Aile Aerosol 貴社の医薬品ニーズに合わせた高精度設計の装置と包括的ソリューションを提供します。

📩 MDIエアゾル充填システムについて詳しくは、今日すぐ当社の専門家までお問い合わせください。

👉 www.aileaerosol.com