In the high-stakes ecosystem of fire safety manufacturing, "capacity" is synonymous with "survival." When market demand spikes—driven by new regulations or urgent safety needs—the manufacturer who can deliver reliable, high-quality products the fastest doesn't just win the contract; they secure the market. Conversely, delays can be fatal to a brand's reputation.

For our latest client, a dominant force in the Argentine fire extinguisher and safety aerosol market, the situation had reached a critical tipping point. Their brand authority was growing rapidly across South America, but their production floor remained stuck in the past. Relying on aging linear machines and a fragmented semi-automatic process, their production topped out at a modest 60 cans per minute (CPM). This bottleneck was devastating. They were effectively bleeding potential revenue, forced to turn away bulk orders or face penalties for delayed shipments. The gap between their sales potential and their manufacturing reality was widening every day.

They didn't just need a new machine to plug a gap; they needed a total manufacturing revolution.

This case study details how Aile Automation stepped in to engineer a comprehensive answer. We delivered a Fully Automatic High-Speed Aerosol Filling Line, a beast of a system capable of running at a sustained 200 CPM. However, speed was only half the battle. The project presented two significant engineering hurdles:

-

Strict Safety Protocols: The product involved highly flammable LPG propellants. Our team integrated top-tier explosion-proof systems, gas detection sensors, and emergency ventilation protocols to ensure that high speed never compromised operational safety.

-

Challenging Factory Layout: The client’s existing facility had a rigid, non-standard layout that couldn't accommodate a standard linear line. Aile’s engineers designed a custom, space-efficient configuration that maximized flow without requiring costly factory expansion.

By transitioning from a labor-intensive 60 CPM process to a fully automated 200 CPM powerhouse, our client has not only tripled their output but also significantly reduced per-unit labor costs. Today, they aren't just surviving the demand; they are dictating the pace of the Argentine market.

1. The Challenge: "Triple Constraint" Engineering

When the client approached Aile Automation, they presented us with what we call the "Triple Constraint"—a scenario where three conflicting factors make the project exceptionally difficult:

A. The Velocity Requirement (200 CPM)

The client demanded a leap from 60 CPM to 200 CPM. In the world of aerosol filling, this is the dividing line between "standard" and "elite." At 200 cans per minute, linear machines are physically incapable of keeping up without causing liquid splashing or can toppling. The only solution is a transition to Rotary (Turret) Technology, where cans are controlled by star-wheels for smooth, high-speed handling.

B. The Spatial Limitation (The U-Shape Necessity)

Speed usually requires length. A standard high-speed line can easily stretch 30 to 40 meters. However, the client's facility in Argentina had structural columns and existing walls that made a straight line impossible. They needed high output in a confined footprint.

C. The Safety Paradox (LPG in Fire Products)

While the product is a fire extinguishing agent, the propellant required for this specific aerosol format is LPG (Liquefied Petroleum Gas). This created a significant engineering challenge: handling a highly flammable gas at high speeds within a factory that must remain 100% explosion-proof.

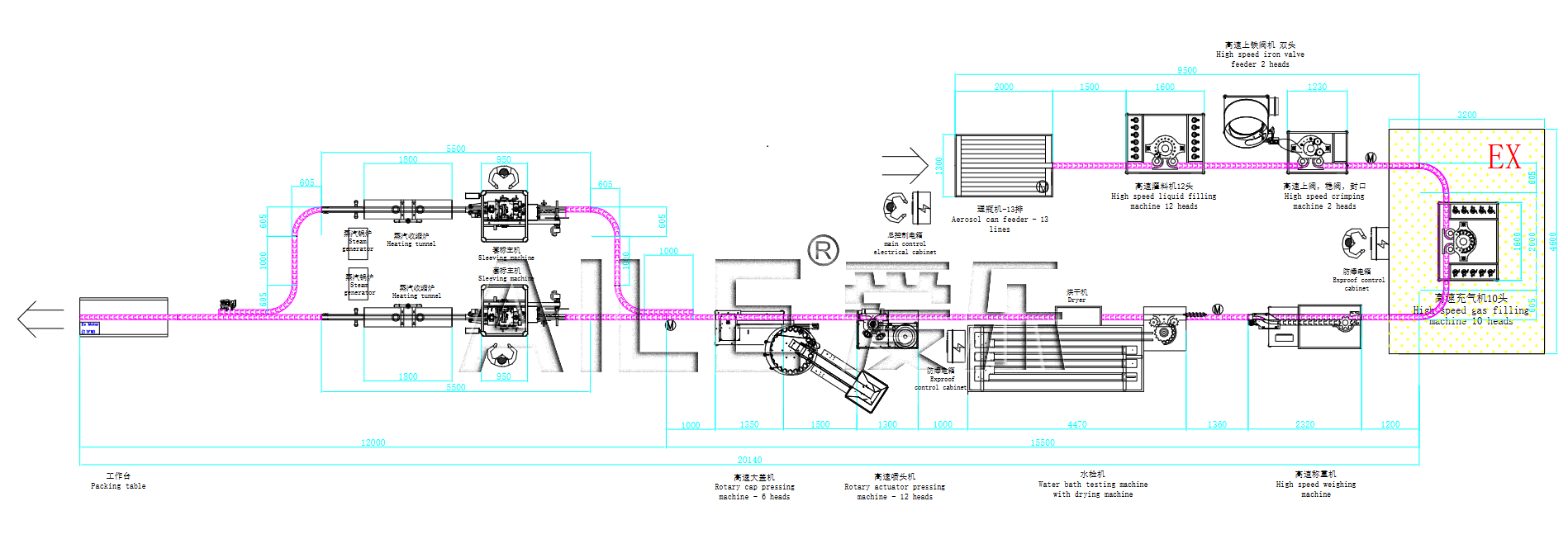

2. The Solution: A Customized U-Shaped Turnkey Line

To solve the spatial challenge, Aile’s engineering team abandoned the traditional straight-line layout. Instead, we utilized Auto-CAD to design a sophisticated U-Shaped Conveyor System.

- Zone A (Preparation): Can feeding and cleaning.

- Zone B (Liquid Filling & Valving): The high-speed rotary section.

- Zone C (The Danger Zone): A specialized, isolated Ex-proof room for LPG filling.

- Zone D (Finishing): Water bath testing, drying, labeling, and packing.

Engineer's Note: “The U-shape isn't just about saving space; it's about operator workflow. By bending the line, we allowed a single operator to monitor both the feeding station and the packing station visually, reducing the walking distance significantly.”

3. Deep Dive: The Core Machinery Breakdown

To achieve a stable 200 CPM, every machine in the line must be synchronized perfectly. A bottleneck in one unit slows down the entire system. Here is the technical breakdown of the line’s "heart and soul."

Step 1: High-Speed Bottle Unscrambler

The Foundation of Speed. At 200 CPM, manual feeding is impossible. We integrated a High-Speed Explosion-Proof Unscrambler.

- Capacity: Rated for 200-250 CPM.

- Mechanism: It uses a centrifugal lifting plate to sort bulk cans and gently deposit them onto the conveyor.

- Innovation: We added a polymer lining to the sorting disc to prevent scratching the pre-printed aluminum cans, a common issue with older metal-on-metal unscramblers.

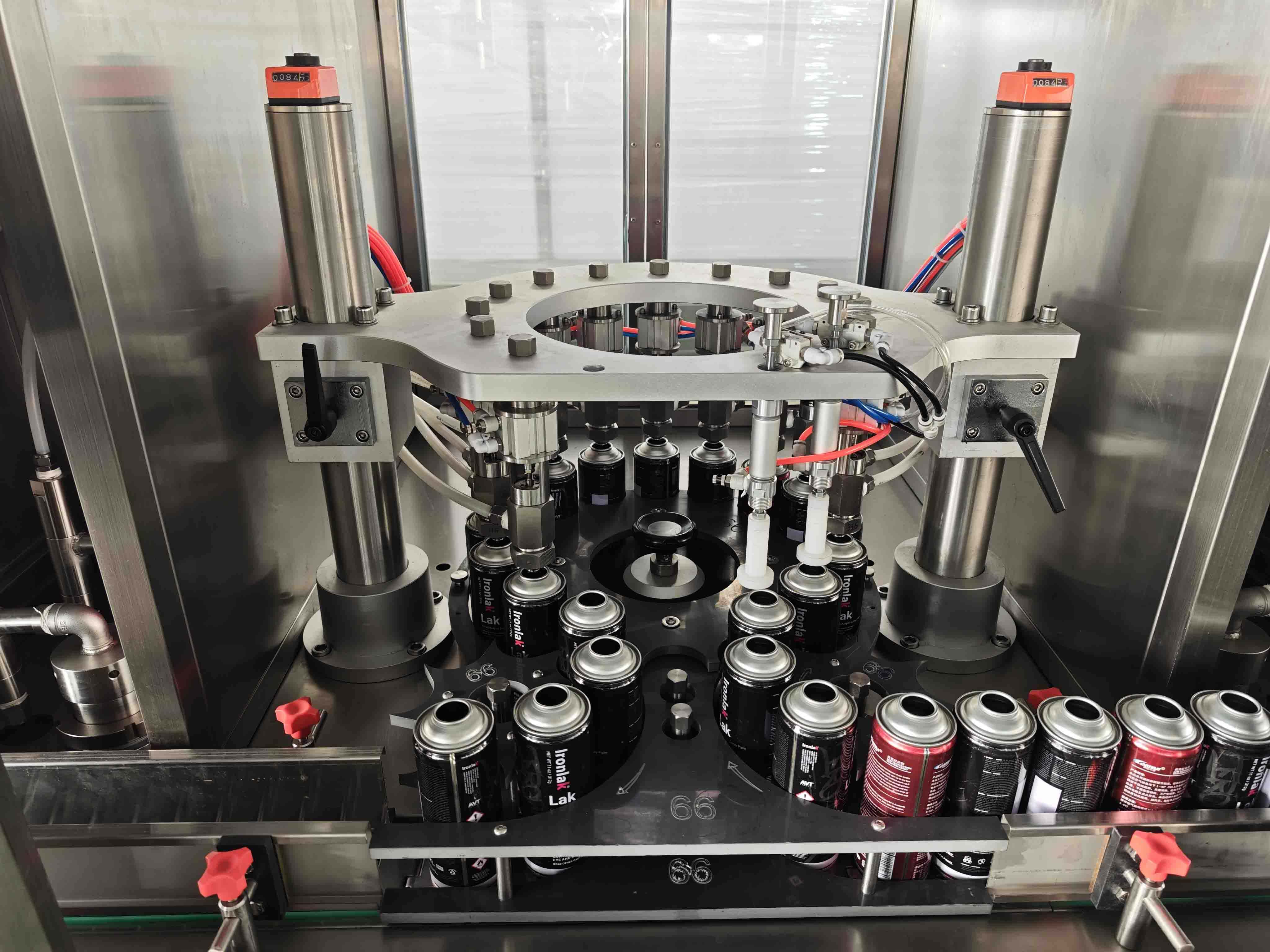

Step 2: The Heart — 12-Head Rotary Liquid Filling Machine

Precision at High Velocity. This is the most critical machine on the line. To fill fire extinguishing fluid (which can be foamy or viscous) at high speeds, we deployed our High Speed 12-Head Rotary Liquid Filler.

- Rotary Turret System: Unlike linear fillers that stop-and-go, this machine fills while rotating. 12 separate filling nozzles track the moving cans, maximizing the filling time window to ensure accuracy.

- Accuracy: ±1% filling error.

- No-Can-No-Fill: An advanced sensor system detects if a can is missing from a star-wheel pocket and instantly prevents that specific nozzle from dispensing, saving valuable raw material.

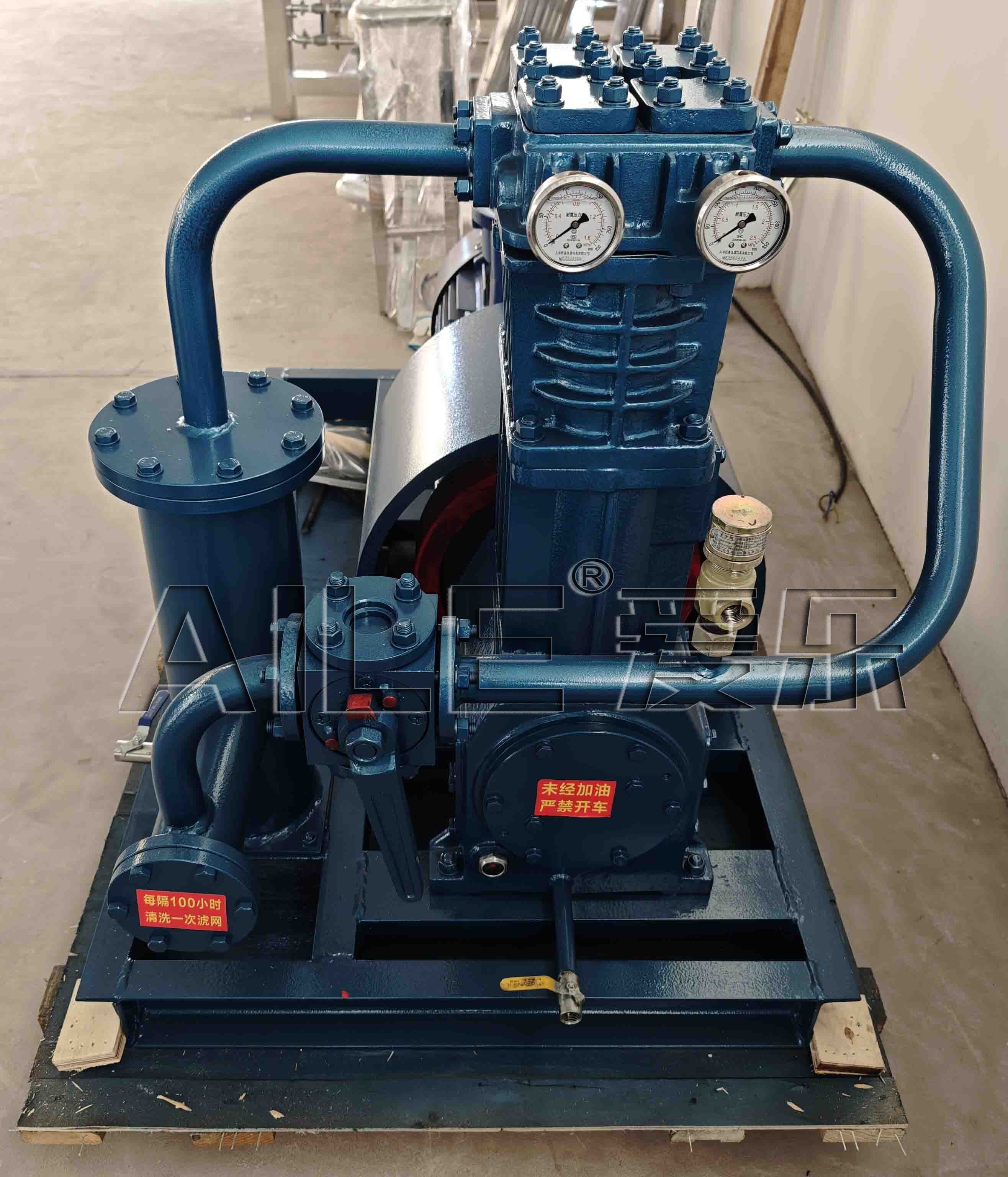

Step 3: LPG Safety System & Rotary Gas Filler

Safety Meets Performance. Since the propellant is LPG, safety is non-negotiable. This machine sits inside a custom-built Explosion-Proof Room.

- Dual-Mode Design: The line is engineered to handle both Nitrogen (for standard extinguishers) and LPG (for multi-purpose aerosols), providing future versatility.

- 10-Head Rotary Gassing: Performs vacuuming and gas injection in a seamless cycle.

- LPG Compressor System: A dedicated booster pump ensures stable propellant pressure, regardless of the external tank level.

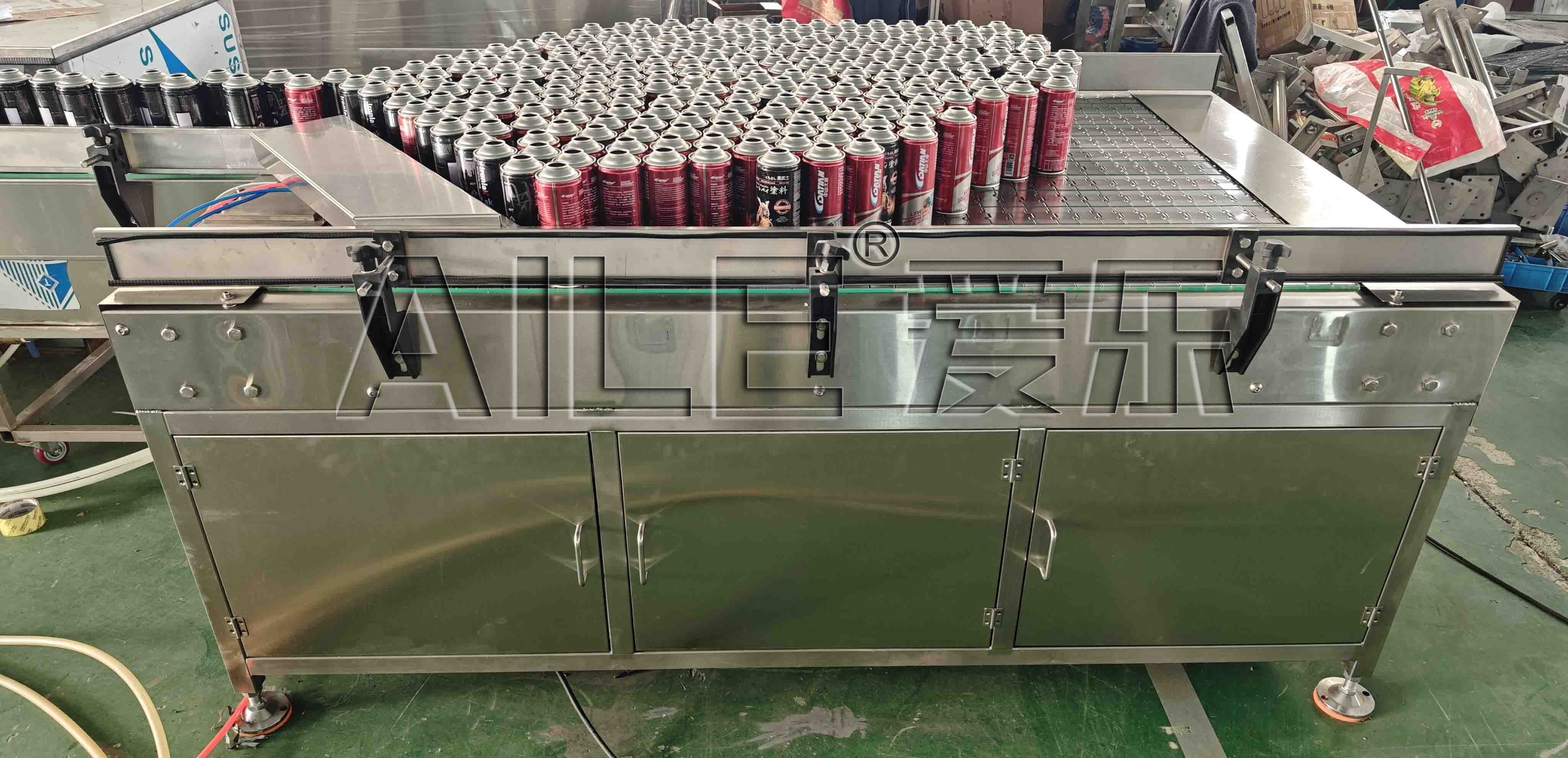

Step 4: Quality Assurance — Water Bath Tester

Zero Defect Policy. For pressure vessels, leaks are safety hazards. Every single can is submerged in warm water to check for leaks.

Step 5: Custom L-Type Nozzle Insertion

Customization for Special Shapes. The client uses a unique "L-Type" spray nozzle. Standard machines often jam with irregular actuators.

- Robotic Pick-and-Place: We designed a specific vibratory bowl and a mechanism to orient and insert these difficult nozzles reliably at 200 CPM.

- Dual-Head Labeling: To keep up with the speed, the labeling station is manned by two operators to facilitate rapid label roll changes without stopping the machine.

4. Operational Efficiency: The ROI Calculation

The true value of this line isn't just in the machinery; it's in the operational economics.

- Speed: Increased from 60 CPM to 200 CPM (330% Growth).

- Staff: Reduced to just 4 Operators (Can Feeding, Gas Room Monitor, Labeling A & B).

- Labor Cost: 70% decrease per unit produced.

The Math: By tripling production while cutting the workforce, the client is projected to recover their investment cost (ROI) in less than 14 months.

5. Factory Acceptance Test (FAT) & Delivery

Before shipping to Argentina, we ran the line continuously for 4 hours during the FAT. The result? Zero jams, filling deviation within 1.5g, and smooth high-speed handling.

The client’s feedback? "We expected speed, but we didn't expect this level of smooth handling. The machine runs like a Swiss watch."

6. Why Choose Aile Automation?

This project highlights why Aile is the preferred partner for complex aerosol projects:

- Engineering Flexibility: We adapt layouts (like the U-Shape) to fit your reality.

- Safety First: Expertise in LPG and explosion-proof systems.

- Turnkey Responsibility: From the compressor to the packing table, we supply it all.

Ready to Upgrade Your Production?

Don't let your production line be the bottleneck of your growth.

👉 Contact Aile Engineering Team Today for a free consultation on your factory layout and high-speed line design.