בסביבה התחרותית של FMCG (מוצרי צריכה מתחלפים במהירות) של אלג'יריה , יצרנים כבר לא מחפשים מכונות בודדות. הם מחפשים מערכות משולבות שמгарנות עקביות, בטיחות וקיבולת גבוהה במיוחד.

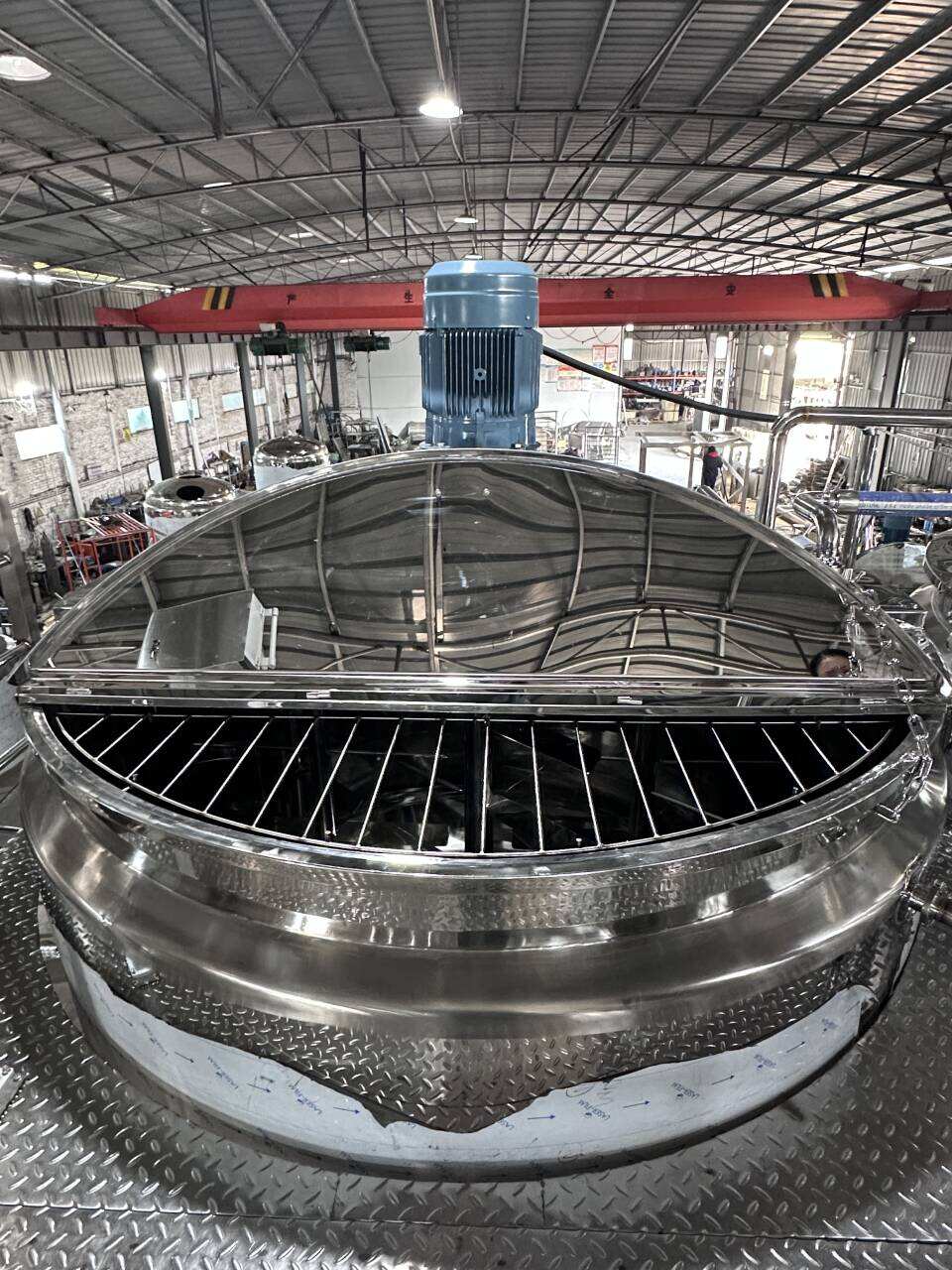

מסירת הפרויקט האחרון שלנו היא עדות לשינוי הזה. פיתחנו, ייצרנו והפעלתנו בהצלחה קו ייצור ענק ל ייצור נוזלי של דטרגנטים וטיפוח אישי שמגדיר מחדש את היעילות. זה לא סתם ציוד; מדובר במערכת אוטומטית לחלוטין שנועדה להתמודד עם יותר מ- 40 טון של חומרי גלם בכל מחזור אצווה .

אופטימיזציה של השטח הייתה דרישה עיקרית מצד הלקוח שלנו. כדי לאכלס את גודל החיות הגדול ללא הרחבה של שטח המפעל, פיתח צוות ההנדסה שלנו תצורת זרימה אנכית בכוח המשיכה המבוססת על שתי פלטפורמות תפעוליות עוצמתיות ומיוחדות.

ההגדרה:

מיכל הוא רק נירוסטה עד שנותנים לו אינטיליגנציה. הקו הזה כולל שילוב טכנולוגיה אירופאית מדרגה ראשונה.

כפי שנראה בתמונות של לוח הבקרה, כל המתקן מחובר לרשת.

דיוק הוא ההבדל בין מוצר טוב למוצר מעולה. ביטלנו מדדי זרימה טרديציוניים לטובת מדידה גרמטרית .

היופי של קו זה נמצא ב מערכת הצינורות המחוברת :

בטיחות אינה אפשרות; זו עדיפות. טיפול בכליות של 12 טון מעורב בעבודה בגובה, ועשינו לעצמנו את המערכת כדי להגן על הנכס היקר ביותר: צוות העובדים שלך.

הפרויקט הזה מייצג את שיא היכולות ההנדסיות שלנו. אנחנו לא רק מספקים מיכלים; אנחנו מנתחים את זרימת העבודה שלכם, מעצבים את התכנון שלכם ומממשים אוטומציה להצלחה שלכם.

רוצה לראות עוד תצורות?

גלושו לקטלוג המלא של המוצרים והمواصفות הטכניות >>

בין אם אתה באלג'יר, דובאי או באירופה, צוות ההנדסה שלנו מוכן לעצב עבורך פתרון מותאם אישית.

יצירת קשר לייעוץ טכני